The LEVIS H2020 project concludes by demonstrating the significant environmental, economic and technological benefits of advanced lightweight materials

Lightweight is an indispensable feature in automotive applications in general, and especially in electric vehicles, since it contributes to improving vehicle efficiency in terms of kWh consumed per km and vehicle range. Reduced weight will lead to faster market growth of EVs replacing traditional internal combustion engine vehicles, which will ultimately contribute to reaching the target greenhouse gas emissions reduction by 2050.

In this context, Leartiker Technology Centre has been involved in the LEVIS Green Vehicles initiative for 4 years, a European Union Horizon 2020 project that aims to develop technology pillars that will enable industries to design and produce lightweight, cost-effective and sustainable components for the electric vehicles of the future. This initiative, which started in February 2021, has come to an end with magnificent results.

By adopting an eco and circular design concept all the way from the design phase up to the end-of-life stage, LEVIS has developed, verified and demonstrated lightweight components and structures for electric vehicles with enhanced sustainability, improved raw material use, energy and cost efficiency, and reduced weight with yet high structural integrity and reliability. LEVIS’ results have been built on the use of multi-material solutions based on fibre-reinforced thermoplastic composites integrated with metals, produced using cost-effective and scalable manufacturing technologies. The benefit and competitiveness have been showcased through three real-case demonstrators: a suspension control arm, a battery holding set and a cross-car beam.

LEVIS project video

30% weight reduction and recycling rate of more than 80%

New sustainable materials, suitable manufacturing/assembly procedures, advanced simulation methodologies/workflows and innovative sensing/monitoring technologies have been developed, implemented and validated. Recyclable resins and bio-resourced and recycled CFs have been developed and used for enhanced sustainability. A circular-design approach has been adopted for constructing the structural parts to maximise their service life and enable easy, effective and efficient dismantling and recovery of the materials with sufficient quality for second use.

These efforts achieved an average weight reduction of 33% and introduced novel one-shot production techniques to reduce costs and enhance efficiency. Environmentally, the project implemented strategies guided by eco-design principles to minimize environmental impact across all phases of product life. This included achieving up to 85% recyclability of multi-material components and reducing global warming potential by at least 23% at the component level compared to conventional benchmarks.

Economically, LEVIS technologies showed broad market applicability, with the potential of being adapted to over 60% of vehicle chassis and body components, suggesting significant industry-wide benefits.

LEVIS White Paper Released

The LEVIS project has published also a white paper, “Advancing Lightweight Materials for Sustainable Electric Vehicles: Policy Recommendations from the LEVIS Project” This comprehensive document provides targeted policy recommendations aimed at accelerating the integration of advanced lightweight materials into the production of sustainable electric vehicles (EVs).

Grounded in the successes and insights of the LEVIS project, the white paper outlines significant environmental, economic, and technological benefits that advanced lightweight materials offer. It identifies key barriers, such as high costs, technological gaps, and market resistance, that hinder wider adoption. The paper advocates for comprehensive policy support, including financial incentives, enhanced R&D funding, and strategic regulatory changes, to facilitate this critical transition.

Leartiker in the LEVIS project

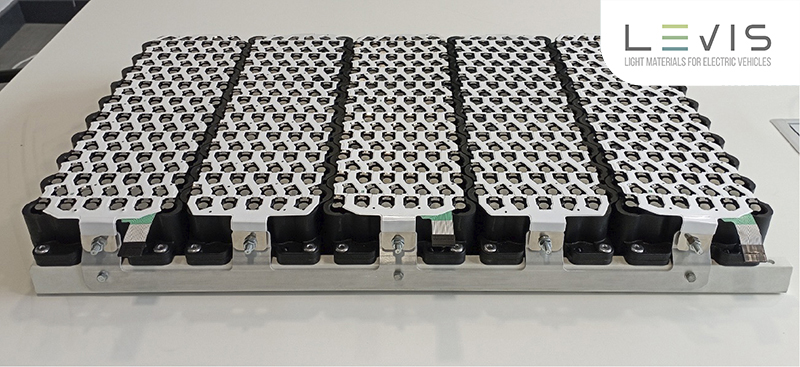

Leartiker has been the responsible of one of the demonstrators, a battery module, but has also collaborated with TOFAS and the AIMEN technology centre in the development of another demonstrator, the cross-car beam.

The battery module is a component based on a recycled polymer structure that integrates the bus bar and monitoring to ensure the correct functioning of the battery. In the delevopment of this sub-component Leartiker has collaborated with the project partners Mersen Electrical Power, CEA-Liten and Privé (Progettazione Ricerca Ingegnerizzazione Veicoli Elettrici), and together with partners MERSEN and CEA has carried out the final validation and assembly of the module housing with the rest of module components, the busbar and monitoring parts.

Battery module – Integration of busbar with injection molded thermoplastic composite housing.

Related technologies: process & structural simulations and optimization, thermoelectric simulations, fuse functions introduced at cell level, printing technologies, sensors and temperature and voltage monitoring systems integration, recyclable materials.

Steering column carrier – Integration in cross car beam.

Related technologies: process & structural simulations and optimization, recycled carbon fibers, one-shot process, superficial laser treatment, recyclable materials.

More information: https://greenvehicles-levis.eu/

__________

#GreenvehiclesLEVIS partners:

ITAINNOVA · Instituto Tecnológico de Aragón

Marelli

Mersen | Electrical Power

Privé S.r.l. - Production Research Industrialization Vehicle Electric

Yesilova Group

TOFAS

AIMEN Centro Tecnológico

CANOE - Le Centre Technologique Nouvelle Aquitaine Composites & Matériaux Avancés

RISE Research Institutes of Sweden

CEA-Liten

Cenex Nederland

Steinbeis Europa Zentrum

Leartiker