Development of Components for Electric Vehicles using Polymer Over-Injection and Welding Technologies (Success Story)

During the 2023-2024 financial years, and within the framework of the Hazitek programme (Basque Government), Leartiker has carried out an industrial research project in collaboration with the company RPK S. Coop., aimed at generating knowledge and experimental development of new commercial opportunities in the field of electric mobility.

Thanks to this initiative, the company has reinforced its technical capabilities in the use of thermoplastic materials and in polymer over-injection and welding technologies, positioning itself strategically to respond to future requests for proposal (RFQ) and access new markets.

General Objective of the Project

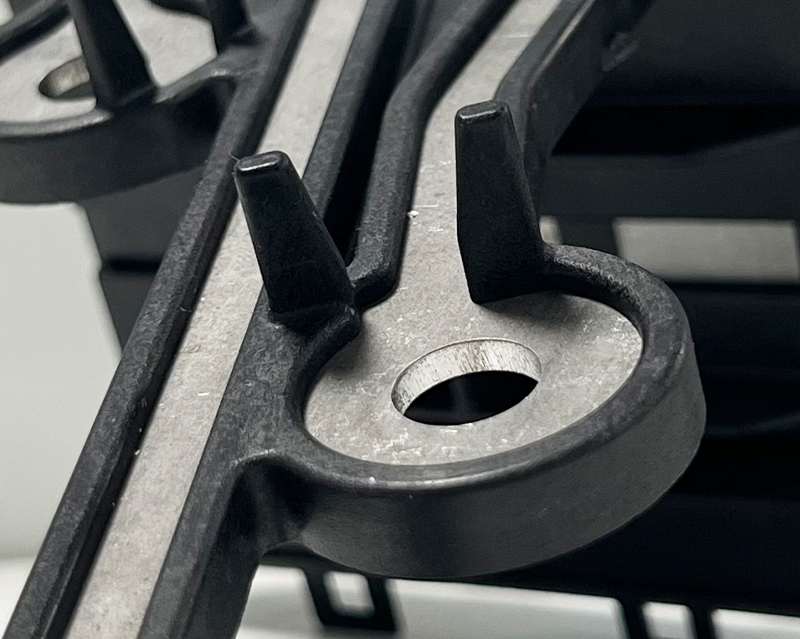

The COMBINE project has focused on the study and development of components for the electrification of vehicles, by combining advanced polymeric materials with metal inserts, using over-injection and ultrasonic welding technologies. Leartiker has participated as a technological partner of the project, providing advice on methodologies for characterisation and validation of materials and components.

Specific Technical Objectives

- Acquisition of technical knowledge on specific polymers for electric vehicle applications.

- Mechanical, electrical and thermal characterisation of polymeric materials.

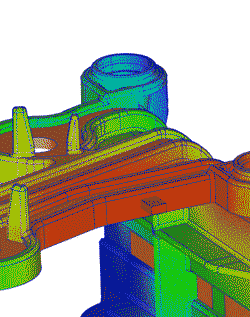

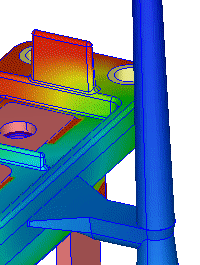

- Simulation and experimental validation of over-injected metal inserts.

- Optimisation of the over-injection process by means of rheological simulation (Moldex3D).

- Study of polymer welding technologies and their behaviour in specific conditions of the automotive sector (e.g. thermal shock).

Methodology and Development

Two main materials were selected for study:

- Polyphthalamide (PPA) reinforced with 30% glass fibre.

- Polyurethane specifically formulated for electric mobility applications.

Two functional demonstrators were redesigned, optimised for injection and over-injection molding. One of the demonstrators was divided into three individual components to facilitate their injection and subsequent assembly by ultrasonic welding.

To define the optimal injection conditions and mold design, rheological simulations were carried out with Moldex3D software, allowing critical parameters such as temperature, pressure and injection speed to be established, as well as the evaluation of the quality and location of the joining lines.

Subsequently, the molds and tooling necessary for the over-injection and welding processes were manufactured.

The prototypes obtained were assembled by ultrasonic welding, a process that required the design and manufacture of specific sonotrodes and clamping tools.

Experimental Validation

- Mechanical tests: Tensile tests were carried out on the welded prototypes, reaching resistances of up to 20 kgf, without failures in the joint lines, which indicates a correct quality of the assembly.

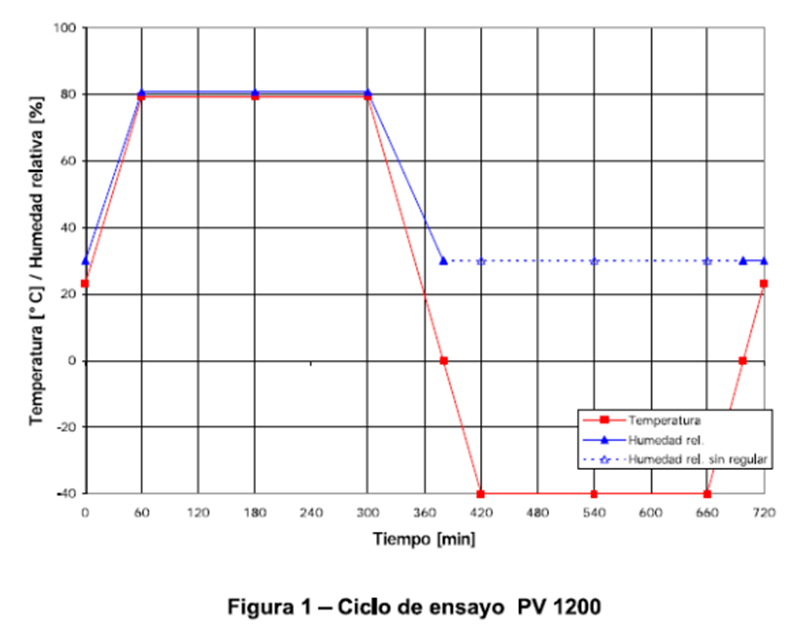

- Ageing tests: A thermal shock protocol was applied in accordance with the PV1200 standard, using a climatic chamber. Subsequent visual inspection revealed no cracks or deformations in the prototypes of any of the materials evaluated.

Conclusions

The project has allowed RPK S. Coop. to acquire advanced technical capabilities in the use of thermoplastic materials for electric vehicle applications, as well as in polymer over-injection and welding technologies. This knowledge positions the company to respond to future RFQs and access new markets in the electric mobility sector.