i-InjLab, a smart laboratory that transforms thermoplastic injection

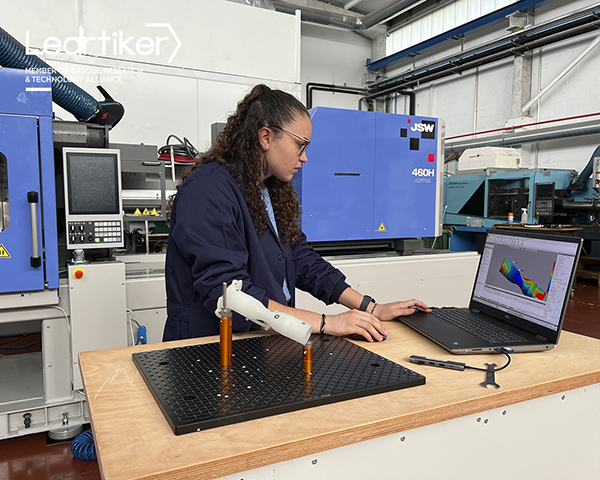

Leartiker has taken a decisive step towards advanced digitalisation and sustainability with the launch of i-InjLab, a smart thermoplastic injection laboratory that marks a milestone in applied research and technology transfer. This new infrastructure, subsidised by the Basque Government - Azpitek, has become a strategic tool for positioning Leartiker as a benchmark in state-of-the-art injection processes.

i-InjLab has been designed to respond to the current challenges facing the industry, integrating artificial intelligence, NIR analysis and real-time control systems that allow the critical variables of the injection process and the properties of the material to be monitored. Thanks to this capability, the laboratory guarantees the traceability, repeatability and quality of the final product, even when working with recycled materials, thus responding to the challenges of digitalisation and sustainability, in line with the RIS3 Euskadi strategy and the 2030 Science, Technology and Innovation Plan.

Pioneering infrastructure

The closed-loop installation allows us to measure key process variables such as pressure, flow, temperature and viscosity of the molten material. These variables are compared with mathematical models that represent the ideal behaviour of the process. The manufacturing cell is equipped with a machine capable of processing parts between 30 and 350 cm³, with on-site injection/compression and rheological control systems that automatically compensate for process variations. It also incorporates a non-contact measurement system to verify deformations and calibrate simulations, reinforcing its role as a key tool in the validation of numerical models.

One of the major advances brought about by i-InjLab is its connection to Moldex3D and Mat Center, which allows simulation models to be fed with real data and machine learning techniques to be applied to anticipate failures, optimise parameters and improve product efficiency. This capability is particularly relevant when working with recycled materials and thermoplastic elastomers (TPE), where material variability requires precise and adaptive control.

Computer-aided engineering (CAE) with real measurement data

Computer-aided engineering (CAE) allows the behaviour of the material during the moulding process to be visualised, optimising the use of resources (material, cycle time) and reducing errors. The actual geometry of the component can be captured and compared numerically with the simulated data to optimise and verify the simulation model.

This comparison between real and simulated components validates the FEM models of simulations, enabling knowledge acquisition and ensuring greater reliability. Trend analysis based on simulated parameters ensures reliability when making decisions about the subsequent process, resulting in more durable and sustainable products.

Promoting research and technology transfer

With direct applications in sectors such as automotive and healthcare, i-InjLab not only boosts Leartiker's research and knowledge transfer capacity, but also enables the generation of scientific knowledge and

the tackling of challenges such as noise characterisation and the virtualisation of the mechanical behaviour of elastomers. In doing so, we strengthen research capacity, foster skilled employment and promote more durable and sustainable products, under the principles of the circular economy.

addresses challenges such as the characterisation of the processing/morphology/properties relationship, and the virtualisation of the mechanical behaviour of elastomers. In doing so, we strengthen research capacity, foster skilled employment and promote more durable and sustainable products, under the principles of the circular economy.

This new facility represents a firm commitment to responsible innovation and technological development at the service of society.