Comparative Analysis of Virgin and Recycled PA6 GF25: Viscoelastic Properties and Long-Term Performance (Success Story)

Comparative Analysis of Virgin and Recycled PA6 GF25: Viscoelastic Properties and Long-Term Performance (Success Story)

The transition toward sustainable materials is driving increased interest in recycled thermoplastics for structural applications. However, ensuring that these materials provide mechanical performance comparable to their virgin counterparts remains a key challenge.

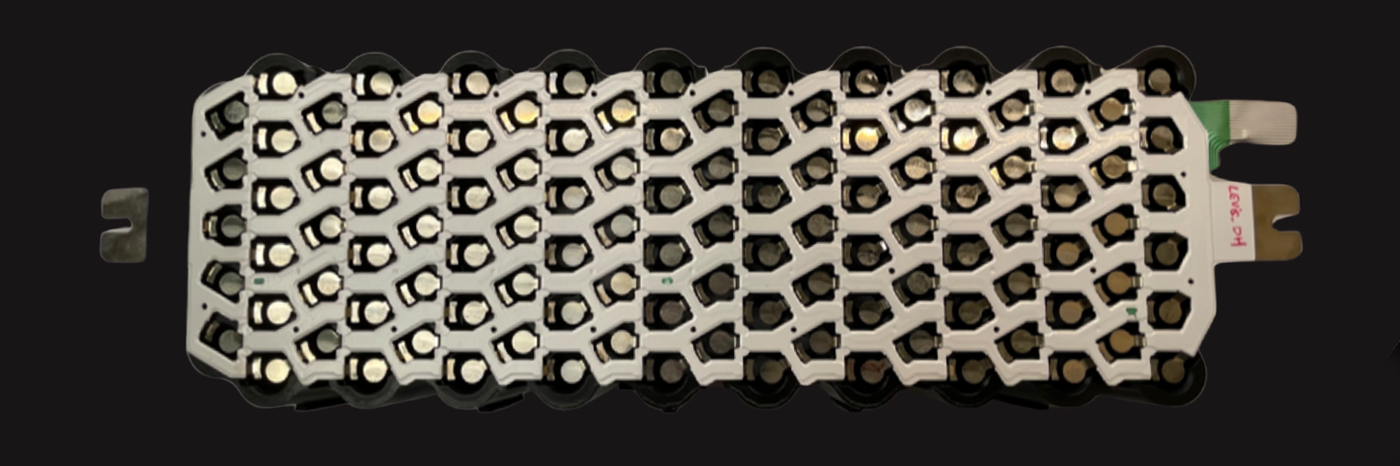

Therefore, here is a successful case study in which we have validated the use of recycled PA6 GF25 for lightweight electric vehicle components. A work that we have carried out in the European project LEVIS Horizon 2020 in which we have developed an eco-designed battery module with integrated busbar and monitoring.

Description

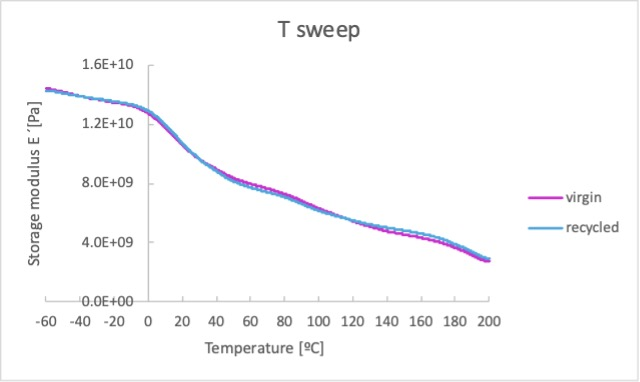

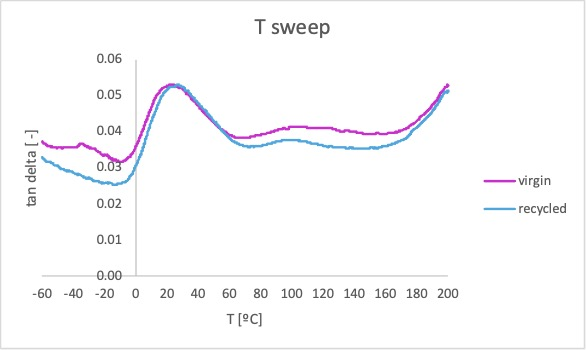

We performed a Dynamic Mechanical Analysis (DMA) on two specialty materials provided by our partner RadiciGroup High Performance Polymers: a virgin polyamide with glass fiber (GF) reinforcement in comparison with its recycled counterpart, containing 20% post-consumer content, to evaluate their stiffness, viscoelastic behavior, and creep resistance.

Methodology

Materials:

- Radiflam® S RV250 HF 333 BK (Virgin PA6 GF25)

- Renycle® S GF2501 HF0 3033 BK (Recycled PA6 GF25, 20% post-consumer content in PA6)

Experimental Setup:

- DMA Thermal Sweeps (−60°C to 200°C, 10 Hz, 3-point bending mode) to analyze storage modulus (E’), loss modulus (E’’), and tan delta evolution.

- DMA Frequency Sweeps (1–400 Hz at 23°C) to assess viscoelastic response at different loading rates.

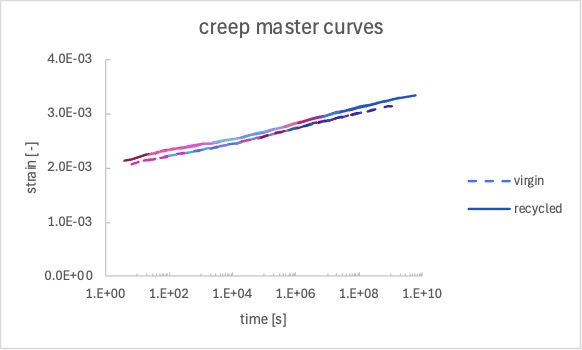

- Creep Tests (15 MPa, 23–70°C) to evaluate long-term mechanical stability, with Time-Temperature Superposition (TTS) used to predict behavior over extended timescales.

All specimens were machined from molded plaques (300 × 100 × 3.2 mm) in two directions (0 & 90º) and conditioned according to ISO 1110.

Key Findings

- Storage modulus (E’): Virgin and recycled PA6 GF25 exhibit nearly identical stiffness trends over the tested temperature range. At room temperature, E’ decreases by ~50% between 0° and 90° fiber orientations, highlighting the material's anisotropic behavior.

- Glass transition temperature (Tg): Both materials show Tg ≈ 30°C, with minor differences in damping. The virgin material exhibits slightly higher energy dissipation, particularly at 0° fiber orientation.

- Creep response: TTS-based master curves indicate that for a projected timescale of up to 32 years, the creep performance of both materials is nearly identical, suggesting that the inclusion of recycled PA content does not significantly affect long-term dimensional stability.

- Anisotropy effects: At 0° orientation, the recycled material exhibits slightly higher creep strain (~3%), but this difference is within experimental scatter. At 90° orientation, both materials show overlapping behavior.

Figure 1: Storage modulus (E´) evolution with Temperature, at parallel fiber orientation (0º) to main filling direction.

Figure 2: Loss factor (-) evolution with Temperature, at parallel fiber orientation (0º) to main filling direction.

Figure 3: Creep strain evolution predicted by TTS, at parallel fiber orientation (0º) to main filling direction.

Industrial Implications

These results confirm that recycled PA6 GF25 retains key mechanical properties, making it a viable alternative for structural applications requiring long-term stability, such as automotive, electronics, and electric vehicle components. The slightly higher damping behavior of the recycled material may even offer advantages in vibration-sensitive environments.

Based on those conclusions, we developed an eco-designed battery module with integrated busbar and monitoring in the framework of the LEVIS project, validating the use of the recycled PA6 GF25 for lightweight electric vehicle components with enhanced sustainability.

What are your thoughts on the potential of recycled thermoplastics in demanding applications? Let’s discuss it.